Linclon Impinger Gas Conveyor Ovens Model 3262-2 - HAS 4 CONVEYOR DECKS

Linclon Impinger Gas Conveyor Ovens Model 3262-2 - HAS 4 CONVEYOR DECKS

C$36,555 (CAD)

Available quantity: 1

Description

LINCOLN IMPINGER2 DOUBLE STACK 4 DECK CHAIN DRIVE / CONVEYOR (GAS) PIZZA OVEN (ENODIS)

BELT SIZE APPROX. 32" WIDE

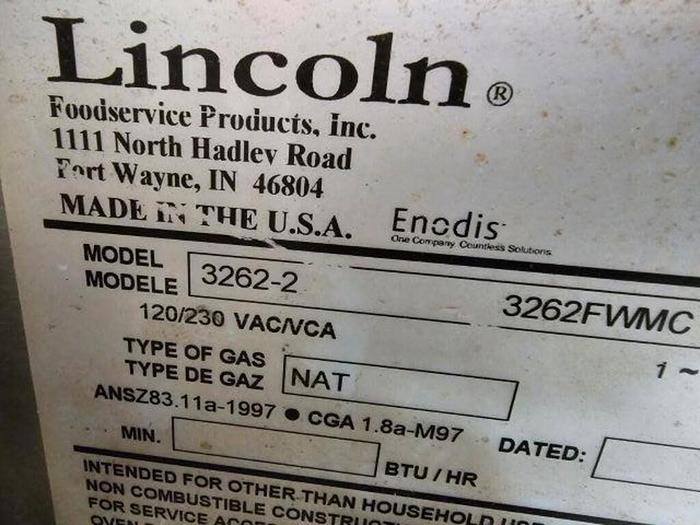

MODEL: 3262-2

NOTE:

Units will be thoroughly cleaned and all faulty or near faulty parts or controls will be replaced including bearings etc.

FEATURES:

- Impinger® X2 uses hot air under pressure which surrounds food with small jets of hot air. This allows for rapid heating, cooking, baking and crisping of foods, two to four times faster than conventional ovens, depending on food product cooked.

- Uniform heating/cooking of food products offers a wide tolerance for rapid baking at a variety of temperatures.

- Variable-speed conveyors move products through the oven one after another, improving product flow during cooking and drastically reducing labor.

- The safety of conveyorized product movement is a definite advantage over batch-type ovens, as it eliminates the need for constant tending.

- Customer-specific air fingers on top and bottom allow for the heat to be adjusted and controlled by zoning.

Digital Controls:

The digital control panel is located at the back right of the oven and has power fan, burner and conveyor on-off switch. It also has one temperature control for the entire oven and conveyor speed controls for every belt. The LED readout displays actual cavity temperature in degrees (F° or C°), conveyor belt speeds and thermostat indicator light.

Unit weighs 1400lbs

Measures 61" x 60" x 104"

GAS SERVICE:

The gas Control system has a manual shut-off valve, internal pressure regulator (factory preset at 3 ½” water column/. 87 kPa or 8.70 mbar for Natural Gas, 10” water column/2.48 kPa or 24.87 mbar for LP gas), and an electric solenoid operated main gas valve. Heat is supplied by one (1) power burner rated at 200,000 BTU/Hr. (126MJ) with electronic ignition. Natural gas requires 8” WC mbar inlet with a maximum allowable of 14” WC mbar. LP gas requires 13” with a maximum allowable of 14” WC. The gas line from the meter to the ovens should be 2” for natural gas and 1 1/2” for propane. AGA/CGA design approved flexible connection to each oven must be ¾” NPT and length must not exceed 6 ft. (1829mm).

VENTILATION:

Ventilation is required. Local codes prevail. These are the “authorities having jurisdiction” as stated by the National Fire Protection Association, Inc. in NFPA 96-1994. Consult Impinger X2 Installation and Operations Manual for ventilation recommendations.

SPACING:

The oven must have 1” (24.5mm) of clearance from combustible surfaces and 24” (610mm) clearance on both sides from other cooking equipment. A permanently installed oven requires approximately 3ft. (882mm) of clearance overall to allow for the removal of the conveyor and protective guards for cleaning. The conveyor is removed from the front of the oven.

Shipping: You can either contact us to receive a shipping quote or you can arrange the shipping yourself. If you would like us to arrange the shipping be sure to include the name of your business, your email address, a good contact telephone number, whether this is going to a business or residential location and also if you will need a lift gate to unload it. If you are arranging the shipping, we are a business with a forklift in Postal Code V4N4G6

We generally charge $150 to wrap it in Bubble Wrap and/or Cardboard and Stretch Wrap it before Strapping it to a pallet. If you would like additional protection measures, please contact us.

Specifications

| Manufacturer | Lincoln Food Service Products |

| Model | Model 3262 |

| Condition | Refurbished |

| Stock Number | PO-281-0415-382 |